What is the working principle of the Electric Traction Hoist Motor

In our company, the working principle of the Electric Traction Hoist Motor relies on the perfect combination of motor drive and gear transmission system, and the precise lifting and lowering of the Suspended Platform is achieved through wire rope or chain.

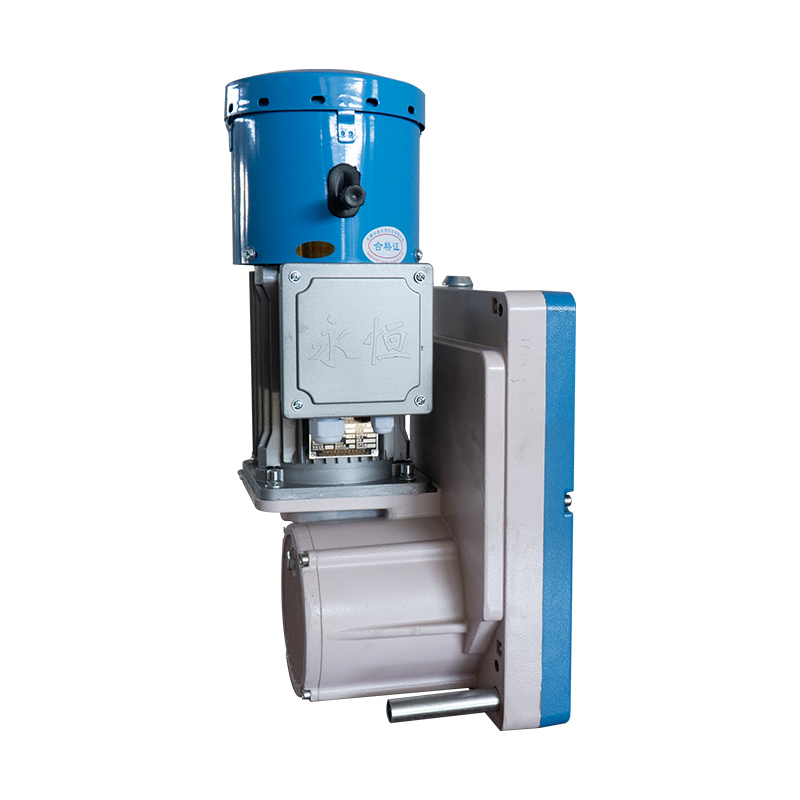

The motor is the core power source and provides stable rotation. We use high-quality AC or DC motors to ensure strong power. The high-speed rotation is converted into low-speed, high-torque movement through the reducer. The reducer adopts a worm gear or planetary gear structure with moderate output speed and strong torque.

The drum or winch is responsible for winding and releasing the wire rope or chain, which is connected to the Suspended Platform. As the drum or winch rotates, the wire rope or chain is wound up or released in an orderly manner, driving the Suspended Platform up and down. The guide wheel ensures that the wire rope or chain runs smoothly, reduces friction, and avoids deviation from the track.

Safety is our top priority. The hoist is equipped with a brake, which can brake quickly in the event of power failure or emergency to ensure safety. The limit switch detects the position of the Suspended Platform to prevent it from exceeding the predetermined height or falling to the bottom. The overload protection device automatically cuts off the power supply when the load exceeds the standard to protect the equipment from damage.

Easy to operate, the Electric Traction Hoist Motor is equipped with a control panel, and the operator can easily control the lifting of the basket through buttons or touch screen. Some models are also equipped with a remote control for remote operation.

Through this series of precision design and efficient mechanism, our company's Electric Traction Hoist Motor can efficiently and safely complete various lifting and lowering tasks to meet the diverse needs of customers.